Transportation is a notable emitter at 15% of emissions, has already witnessed huge disruption both in manufacturing techniques, and the very nature of the engine which drives the power train.

However, other aspects of transportation are also ripe for renewal. Used tire disposal is a long running sore for most post-industrial societies – with each year, another billion or so, come to the end of their roads. Until recently, tyres were destined for landfills, with all of the attendant environmental concerns that brings. In recent years, more stringent environmental regulations have mandated recycling of tyres – at least in most developed markets. To that degree, tyres have been used to repair roads, or as supplementary fuel for cement kilns for example, or even more crudely, incinerated to provide power. Ultimately, all of those uses are not entirely satisfactory given the planet warming consequences of those additional emissions inherent in each of those solutions.

An alternative remedy, one with a higher ecological and environmental benefit, is to use those very hydrocarbons within the tyres to make low carbon fuels to power the very vehicles they originated from.

Having shed the steel, which braces the structure of the tyre, the shredded remnants are then passed through high temperatures in the absence of oxygen – a pyrolytic process once more. This produces separate compounds being carbon black and a mixture of hydrocarbon gases. These gases are drawn off leaving pure carbon black and having cooled, a proportion liquifies into TPO – Tyre Pyrolysis Oil. Any remaining gases are recycled to fuel the reactor. It is another prime example of a closed loop system, within a circular economy initiative.

Carbon Black is in high demand, which can be used to make new tyres. The primacy of which is to consider the alternative means of producing carbon black – burning of heavy oil residues with the concomitant world warming emissions that brings. The recovered TPO has very similar properties to oil straight from a well head, and hence is well disposed to produce bio-diesel.

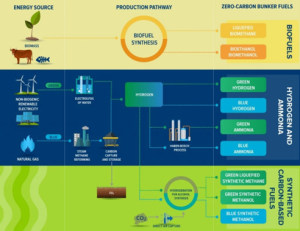

Sea of opportunity for zero carbon shipping

Source: World Bank:

Whilst electric vehicles will ultimately displace 1mn of oil demand per year, demand appears to be flatlining before many had hoped and hence the future of low carbon fuels compared to conventional fuels is still momentous. Furthermore, large commercial transport and shipping is harder to electrify, and alternatives to cleaner maritime fuels perhaps are still commercially unviable. Shipping consumes 5Mbpd of global oil demand, emits 1.5% of the world’s CO2, and adds c1% to the final cost of a typical shipped product, using $1.8/gallon marine diesel at 9.0 kg/gal CO2 intensity. For bulk products such as sugar, iron ore or grains, shipping using marine diesel can comprise as much as 5-10% of product prices, hence switching to the green fuels above can inflate end product costs by 20-30%. As we stand then, the most economic options to decarbonise shipping are through larger and more efficient ships, using high quality low carbon fuels and perhaps coupling these ships with natural based offsets.

Global Demand for Renewable Shipping Fuels

Projected % of Total Marine Fuel Demand by 2050

| Port | Current Renewable Share (2025) | Projected Share (2050) |

| Singapore | 5% | 60% |

| Rotterdam | 7% | 65% |

| Fujairah | 3% | 55% |

| Zhoushan | 4% | 50% |

| Antwerp-Bruges | 6% | 60% |

| Busan | 2% | 45% |

| Hong Kong | 3% | 50% |

| Panama | 4% | 55% |

| Gibraltar | 5% | 50% |

| Shanghai | 3% | 45% |

Shrinking tyre mountains in the meantime is a very comforting notion and dramatically improves the footprint of conventional fuels, whilst shipping, aviation and large commercial vehicle fleet require further breakthroughs to decarbonise competitively. Singapore and Rotterdam currently lead the pack in terms of their LNG, biofuels and green infrastructure capex. An estimated 2trn USD of investment is required in green port infrastructure, and our proprietary waste to wealth bio hubs, optimised through industrial symbiosis modelling, combining pyrolysis, oxidative desulphurisation and conversion distillation technologies which produce renewable, low sulphur and waste derived bio synthetic fuels for road, marine and air transportation.