Waste has always been a problem humans try to ignore. Now, thanks to pyrolysis, it is also becoming a commodity. By heating organic matter in the absence of oxygen, pyrolysis decomposes complex materials into valuable products: biochar, bio-oil, and syngas. It promises to tackle the twin crises of waste management and carbon emissions. Yet the road from laboratory to industrial-scale deployment has been bumpier than a tyre on landfill-bound tarmac.

FROM FIELDS AND DUMPS TO REACTOR VESSELS

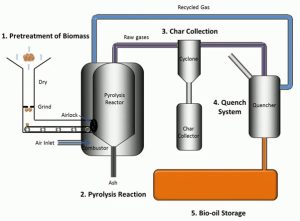

Pyrolysis is deceptively simple. Feedstock—anything from agricultural residues and plastics to old tyres—is heated to 400–800°C in an oxygen-free environment. The chemistry splits molecules, producing:

- Biochar, a stable form of carbon that improves soil and locks carbon away for decades.

- Bio-oil, which can be refined into renewable fuels or chemicals.

- Syngas, a combustible mix of gases suitable for electricity or as a feedstock for chemical processes.

The product slate varies with feedstock: tyres and plastics tend to yield more oil and gas, while biomass produces more biochar. Efficiency can be improved by recycling process heat or using waste gases to fuel the reactors, reducing external energy demands.

“The beauty of pyrolysis is that it turns something society considers worthless into a suite of commercially useful materials,” says Dr. Sofia Legrand, an environmental chemist at ETH Zurich.

THE TECHNICAL HURDLES

Despite decades of research, pyrolysis has struggled to escape pilot-scale operations.

- Feedstock variability remains a persistent headache. Mixed plastics, contaminated biomass, or wet agricultural residues can impair efficiency and product quality.

- Energy intensity is high. Maintaining the necessary temperatures can consume a significant portion of the energy output if not carefully engineered.

- Handling byproducts poses practical challenges. Bio-oil, for example, can be corrosive and chemically unstable, requiring careful storage.

Advances in reactor design, pre-treatment of feedstocks, and process control are starting to overcome these barriers, but scaling remains expensive.

Chart: Showing Typical Pyrolysis Process

CARBON BY ANY OTHER NAME

Pyrolysis has strong environmental credentials, especially when powered by renewable energy. Biochar sequesters carbon for decades, syngas offsets fossil fuel use, and converting waste diverts mountains of plastic and rubber from landfills.

Agricultural residues, plastics, and tyres all have different impacts. Biomass generally scores highest on carbon balance, plastics less so, but the diversion from landfill adds an additional environmental dividend.

“If managed well, pyrolysis can become a cornerstone of a circular carbon economy, not just a waste-handling technology,” notes Prof. John Clancy, head of the Centre for Energy Innovation at Imperial College London.

ECONOMICS: WHEN WASTE PAYS

The business case for pyrolysis hinges on three levers:

- Gate fees: municipalities and waste generators are often willing to pay for the removal of plastics, tyres, or biomass, turning feedstock into an income stream.

- Product value: bio-oil, syngas, and biochar all command market prices. For example, biochar can sell for $400–$1,000 per tonne depending on purity and application, while oil and gas capture fluctuating energy prices.

- Operational efficiency: using waste heat and gas internally can improve net energy balances and reduce costs.

Combined, these factors can deliver returns sufficient to attract private capital. European initiatives, such as the EU Circular Economy Action Plan, provide grants, tax incentives, and regulatory frameworks to support pyrolysis deployment, while countries like Japan and South Korea offer feed-in tariffs for renewable fuels derived from waste.

WHO’S LEADING THE CHARGE?

Several companies are beginning to industrialise pyrolysis:

- Klean Industries: specialises in tyre pyrolysis, producing oil, recovered carbon black, and hydrogen.

- Mura Technology: focuses on plastic pyrolysis, integrating chemical recycling into a circular economy framework.

- Biochar Solutions: converts agricultural residues into biochar, enhancing soils while locking away carbon.

Technology providers are innovating around reactor efficiency, feedstock preprocessing, and continuous operation, helping to bridge the gap between experimental and industrial-scale operations.

CIRCULAR CARBON IN ACTION

Pyrolysis sits neatly within the circular carbon economy. It diverts waste from landfills, recovers energy and materials, and sequesters carbon in biochar. Jobs are another benefit: collection, transport, reactor operation, and downstream processing all create employment. A single medium-scale plant can generate hundreds of positions, from technical staff to logistics operators, providing local economic stimulus while decarbonising energy and materials.

“In a world obsessed with net-zero, pyrolysis allows you to cut emissions, create value, and clean up your streets at the same time,” says Dr. Legrand.

CONCLUSION: TURNING CHEMISTRY INTO CAPITAL

Pyrolysis is not magic. It is chemistry, scaled with engineering and financed with patience. Its promise lies in converting diverse waste streams into valuable materials while contributing to climate mitigation. Investors are taking note: the combination of gate fees, product revenues, and carbon value creates a compelling investment case.

If technical hurdles can be overcome, pyrolysis may become not just a waste-management tool, but a cornerstone of the circular carbon economy: profitable, sustainable, and wryly satisfying—a rare triple in today’s energy landscape.